Introduction

Today, the use of materials and compounds that have high strength and low weight has gained great importance in various industries. Especially in the automotive and aerospace sectors , we see the application of highly functional materials , such as fiberglass and carbon fiber.

Carbon fiber is generally more expensive than fiberglass, but it offers greater strength and versatility while being lighter.

However, fiberglass maintenance is better and more environmentally friendly. Now that we’re at Best German Car Services, a reference for buying German car body parts online alongside providing educational materials, we will look at and compare these two very useful materials in the automotive industry: fiberglass vs . carbon fiber. So , join us

In general, fiberglass and carbon fiber materials have different characteristics and applications. They are made of lightweight, durable composite materials and differ significantly.

If we want to mention the differences between fiberglass and carbon fiber, it should be noted that fiberglass is primarily made of glass fibers. Because it is insulated and resistant to corrosion, it is mostly used in industries such as boating and automotive.

While it is also resistant to temperature changes and weather conditions, it has less strength and more weight compared to carbon fiber.

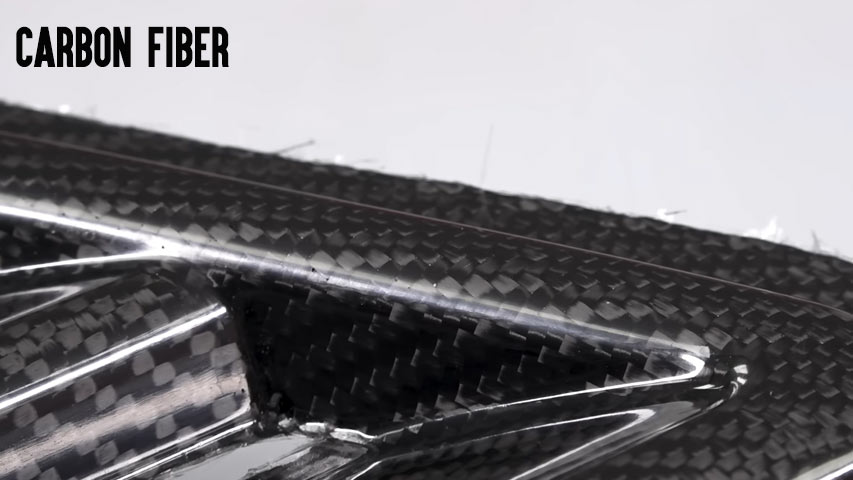

In fact, it is the high strength and lighter weight of carbon fiber that make it suitable for advanced industries such as aerospace and automotive

Difference Fiberglass vs Carbon Fiber

| Comparison Cases | Fiberglass | Carbon fiber |

Fiberglass vs Carbon Fiber Car

Basically, composite materials like fiberglass and carbon fiber have attracted a lot of attention in the automotive industry because of their special features.

However when comparing fiberglass and carbon fibr in automative applications , it should be noted that the low cost and easy formability of fiberglass, which is made of glass fibers, have made it widely used in the manufacture of car bodies.

In fact, it has a good strength and a low weight,making it a great option for producing various parts.

On the other hand, carbon fiber, which has much greater lightness and strength and at the same time higher cost, is used in special projects and racing cars.

It is a very useful material that allows manufacturers to make high-quality, low-weight parts.

However, it should be noted that fiberglass is more affordable due to its low price and reasonable efficiency.

But carbon fiber is an advanced material used in special cases or high technical needs.

Weight difference between Fiberglass and Carbon Fiber

But if we want to compare the weight difference between fiberglass and carbon fiber, we can say that carbon fiber has an average density of 1.9 to 2.3 grams per cubic centimeter, which is lighter than fiberglass, which has a density of about 2.6 grams per cubic centimeter For example, to achieve the same strength as a 1 mm carbon fiber layer, fiberglass with layers of 1.5 to 2 mm thickness is required.

So if a fiberglass car hood weighs about 10 kilograms, the carbon fibr hood weighs only 5 kilograms. This reduction has a significant impact on acceleration, fuel consumption , and vehicle handling.In addition, less weight puts less pressure on the car’s suspension and braking system, increasing the lifespan of the parts

Fiberglass vs. Carbon Fiber Pickleball Paddle

Basically, the choice between fiberglass and carbon fiber pickleball paddles depends on a variety of factors, including skill level, play style, and budget.

However, their manufacturing is also effective.

We want to help you choose one of these two better by comparing fiberglass vs carbon fiber pickleball paddles.

In principle, carbon fiber paddles offer higher control and accuracy because they are more robust and rigid.

Their lighter weight also helps to increase speed , but they’re more expensive and harder to fix . On the other hand fiberglass paddles are more affordable and more flexible , providing softer hits and less pressure on the wrist.

Additionally, they are more resistant to impact, offer less precision, and are easier to repair.

Fiberglass vs. Carbon Fiber: Pros and Cons

Fiberglass vs. Carbon Fiber Cost :

One of the important factors that can help you choose between fiberglass and carbon fiber is familiarity with the cost differences.In principle, fiberglass is a more economical option due to its simpler production process and cheaper raw materials , making it better for producing high-volume parts. Fiberglass equipment is also simpler and cheaper than carbon fiber.

Carbon fiber, on the other hand, is low in weight and high in strength, making it a popular option , but it comes with a higher production cost and requires more advanced equipment.

However, it should be borne in mind that factors such as the type of resin, the number of layers, the complexity of the shape of the parts , and the volume of production also affect the cost

Fiberglass vs. Carbon Fiber Helmets

When choosing a helmet, its material is as important as its appearance and price. In this section, we will compare fiberglass and carbon fiber helmets.

Essentially, fiberglass and carbon fiber are the two main materials used in helmet manufacturing.

While fiberglass is a more economical option, it is heavier and has a lifespan of about 3 to 5 years, which is shorter than that of carbon fiber, which lasts 5 to 7 years. Additionally, fiberglass has less impact resistance.

In fact, a carbon fiber helmet, which is lighter, stronger, and has a modern appearance, offers a longer lifespan and is a better and more attractive option, although its price is significantly higher.

Factors such as budget, weight, performance, and appearance also play a crucial role in the selection process .

Fiberglass vs. Carbon Fiber vs. Kevlar

Compared to fiberglass, vs carbon fiber, and Kevlar, it can be said that each is known for its unique characteristics. High-strength, lightweight carbon fiber is suitable for sensitive applications such as aerospace and racing cars ; however, It’s expensive.

Fiberglass is also an economical option that has good strength and ease of production, making it suitable for construction and boating.On the other hand , Kevlar ,with excellent resistance to impact and wear, is chosen for safety equipment and bulletproof vests. We have also compared these three materials in the table below:

Fiberglass vs carbon fiber vs Kevlar

| Comparison Cases | Carbon Fiber | Fiberglass | Kevlar |

| Tensile strength | Very High | High | Very High |

| Degree of Stiffness | Very High | High | High |

| Weight | Very Light | Light | Very Light |

| Impact Resistant | Medium | High | Very High |

| Heat Resistant | Top | Top | Top |

| Resistant to Chemicals | Top | Top | Top |

| Common Usage | – Aerospace – Racing cars – Professional sports equipment | – Construction – Car manufacturing – Boat Building | – The bulletproof – Safety equipment like vests – Professional sports equipment |

| Price | Top | Medium | Top |

Summary

In this article, we aimed to provide a comprehensive comparison of fiberglass and carbon fiber. This comparison revealed that we are dealing with materials that possess unique characteristics.

Fiberglass is utilized in the construction and automotive industries for its affordability and ease of production.

Carbon Fiber, on the other hand, is employed in various sectors such as aerospace and racing cars due to its lightweight and high strength.

Additionally, we discussed the application of this second material in paddleball rockets and helmets, outlining the advantages and disadvantages of each.

Ultimately, the choice between these two commonly used materials depends on your project needs and

budget .